Ammonia Refrigeration Lubricants

Better Performing Lubricants for Ammonia Systems

CPI Fluid Engineering lubricants are specifically designed to operate with optimal performance in ammonia (NH3) refrigeration systems. CPI lubricants can provide cost benefits through extended drain intervals, fewer filter changes, and less downtime. These lubricants also minimize the amount of NH3 that dissolves, aiding in enhanced lubrication.

Semi-synthetic and synthetic lubricants provide improved performance in ammonia-based refrigeration systems over traditional mineral oils. Benefits include:

Cleaner operation

- Oxidatively stable – reduced sludge and varnish build-up, longer system life

- Corrosion protection – enhanced system reliability, reduced down-time

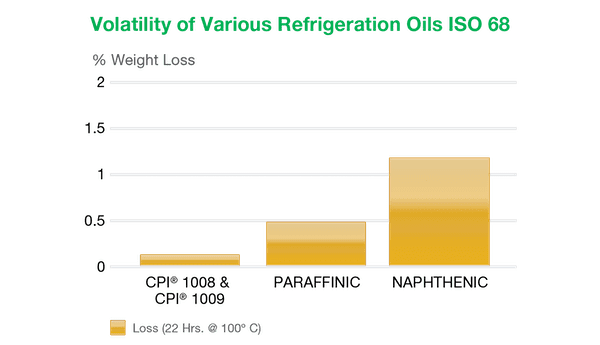

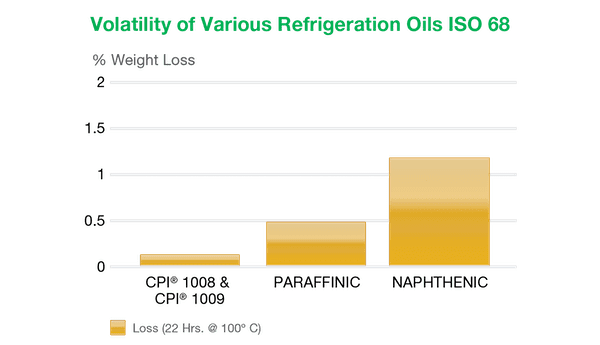

Low volatility

- Decreased maintenance

- Significantly reduced lubricant consumption

Low carryover

- Improved evaporator efficiency

Low pour point

- Easier oil removal

Cost savings

- Longer oil life

- Reduced oil changes

- Extended drain interval

The charts below show the improved low temperature characteristics that CPI lubricants can provide.

Volatility of Various Refrigeration Oils ISO 68

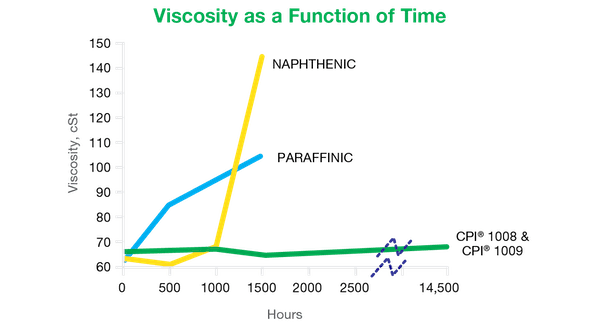

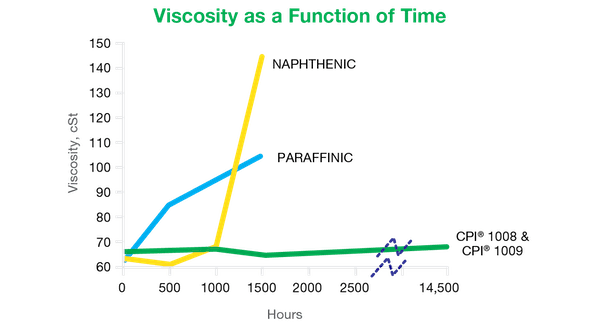

Viscosity as a Function of Time

CPI Fluid Engineering is your one-stop shop for all of your ammonia lubricant needs. We have solutions for every application, whether your system runs at low temperatures or direct expansion. To minimize potentially harmful leaks, we offer patented seal swell technology in many of our formulations. All of our ammonia lubricants are acceptable for use in food and beverage processing facilities (NSF certified), so you can feel confident that our lubricants can be used in these applications as part of a HACCP plan. CPI has products that have been certified Kosher & Halal for food and beverage processing operations producing products that serve the needs of Jewish and Islamic populations.

- Hydrotreated Mineral Oils (HTMO)

- Polyalphaolefin (PAO) synthetics

- Polyalkylene glycol (PAG) lubricants

- Partial synthetics

- Food Grade Options